ICCI's machinery and equipment for quality inspection of construction projects

During the construction inspection process, the construction inspection company must have the capability to operate in construction, and the individuals involved in the quality inspection must meet the professional requirements. Additionally, during the collection of real-time data on-site, if experimental methods are used, it is necessary to utilize laboratories like Las, which are officially recognized and certified for operation.

ICCI commits to safety and sustainability for clients' projects, proposing appropriate inspection methods and equipment for the intended purpose. ICCI's advantage lies in owning its own laboratory, which allows for quality control, reduced timelines, and optimized costs. The LAS-XD 203 laboratory is officially recognized and certified by the relevant authority for operation (refer to Certificate No. 149/GCN-BXD for LAS-XD 203's recognition by the Ministry of Construction as a company qualified to operate specialized construction experiments).

ICCI's machinery and equipment always meet the following three requirements:

- High accuracy, minimizing errors during construction.

- High working efficiency, saving energy and reducing operational costs.

- Regular calibration by a reputable organization to ensure accuracy and reliability of the calibration process.

The equipment and machinery used in construction inspection activities at ICCI are always used in accordance with current regulations (with periodic calibration certificates as required), in good working condition and suitable for the job.

Methods and equipment for on-site inspection of certain tasks (this is not all tasks applicable to all projects, actual tasks performed will depend on the purpose and specific requirements when ICCI establishes the work content):

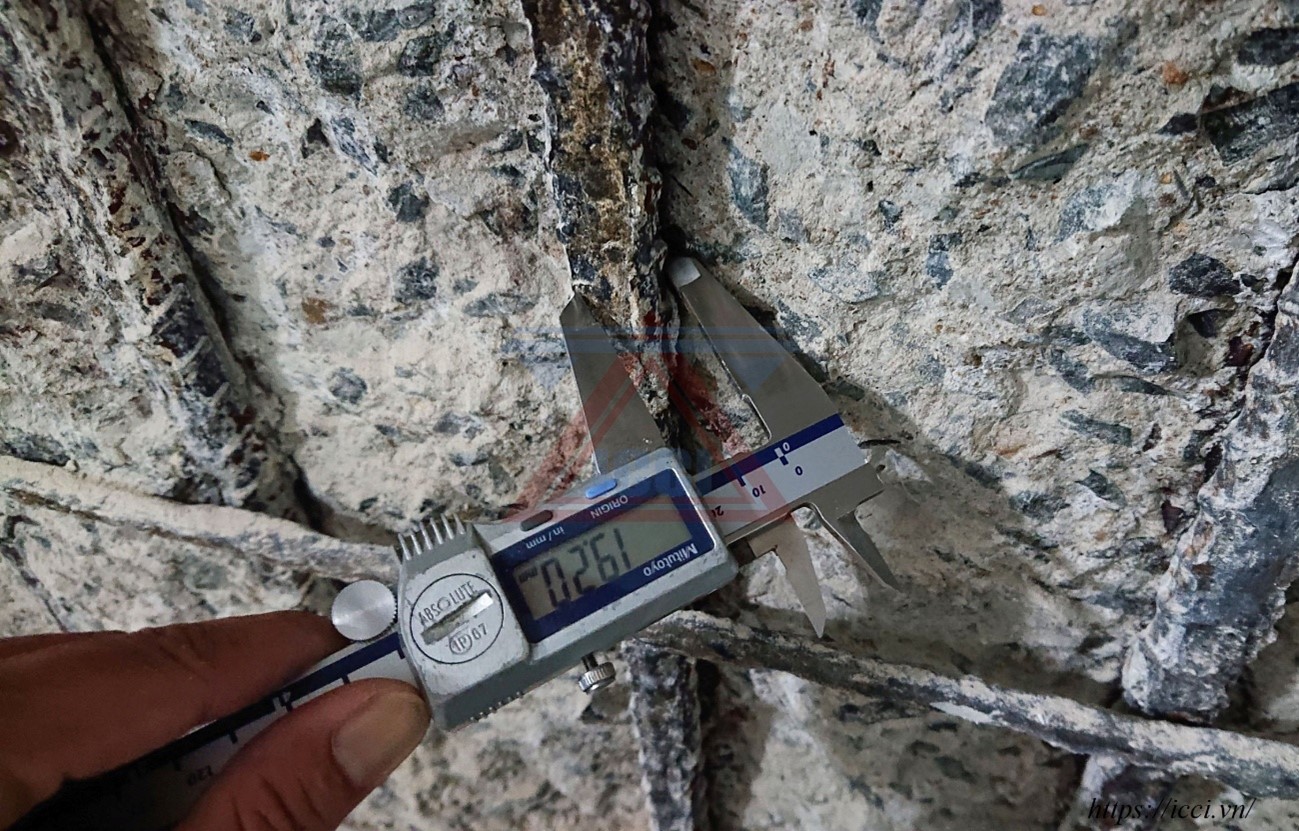

- Measuring and surveying the current state of the construction: Performed manually, combined with visual observation, using cameras, steel rulers, calipers, and crack width measuring devices.

ICCI uses electronic calipers to survey the current state of the construction during construction inspection

ICCI uses depth measuring devices for crack inspection during construction

ICCI uses devices to measure the length and width of cracks during construction inspection

- Checking the geometric dimensions of steel and reinforced concrete components: Performed manually, direct measurement with steel rulers, calipers, and ultrasonic metal thickness gauges..

ICCI uses steel strength measuring devices to check the geometric dimensions of components in construction inspection

- Bolt connection inspection: Performed manually, direct measurement with steel rulers, calipers, and torque wrenches.

ICCI uses a torque wrench to check the tightening force of bolts during factory inspection

- Quality inspection of welds: Performed using ultrasonic methods.

ICCI uses ultrasonic devices to inspect welds during the inspection process

- Checking the remaining dimensions of corroded steel: Performed by removing the surface rust layer and directly measuring with steel rulers, calipers, and ultrasonic metal thickness gauges.

ICCI checks the geometric dimensions after removing the surface rust during the inspection process

- Corrosion testing of steel reinforcement in concrete on-site using the Elcometer THD 331, Bosch hand drills, and sandpaper method.

ICCI uses a device to determine the rusting potential of steel reinforcement in concrete (electrical potential probe)

- Checking the strength of concrete: Can use the destructive method of drilling concrete cores directly on-site and then processing and compressing them in the laboratory, combined with non-destructive methods using ultrasound or rebound.

ICCI drills concrete during construction inspection

ICCI uses a rebound hammer to test concrete strength during construction inspection

ICCI uses a device to measure the thickness of the concrete protective layer for steel reinforcement. Determining the number, position, and estimated diameter of steel reinforcement (electromagnetic steel reinforcement probe) during construction inspection

- Checking the chloride content in concrete

ICCI uses auxiliary equipment to collect powder samples for chloride content testing during construction inspection

- Checking verticality and deflection: Performed using surveying methods, using electronic total stations like Leica.

ICCI uses an electronic total station Leica during the inspection process

Inspection methods in the laboratory and office:

- Processing concrete samples drilled on-site according to the specifications in standard TCXDVN 239:2006, then compressing them to determine strength using the Phoenix compression machine.

- Processing the data collected on-site.

- Calculating and evaluating data using computers through specialized software like etabs, safe, etc., and related standards.

At ICCI, you will notice a difference in each inspection service ICCI provides.

1. Quality and Reliability: Commitment to ensuring top-quality and reliability, minimizing risks.

2. Experience and Credibility: Extensive experience and established credibility of ICCI in the construction inspection industry.

3. Cost: Reasonable costs and ensuring high quality, meeting customer needs.

4. Professionalism and Legal Compliance: Always up-to-date and compliant with current legal regulations, standards, and norms.

5. Technical Support and Consultation: In-depth consultation, ensuring expertise.

6. Machinery and Equipment: Ensuring accuracy and efficiency.

7. Transparent Reporting: Detailed and transparent inspection reports, easy to follow and evaluate.

8. Focus on Long-Term Partnership: Building and maintaining long-term relationships aimed at stability and trust.

9. Risk Control: Always updating new safety regulations, managing potential risks.

ICCI is not just a service provider but also a partner accompanying you on the journey of caring for and developing the health of your construction projects

Vietnames

Vietnames English

English