Structural assessment of reinforced concrete structures with corrosion

When steel in concrete corrodes, the surface of the concrete may also develop cracks that resemble shrinkage cracks. If the inspector lacks knowledge of metal corrosion, they may choose conventional inspection methods (cracks due to shrinkage, overloading, lack of expansion joints, etc.), leading to an inaccurate inspection result for the structural engineer to handle. This article will discuss some basic steps for evaluating reinforced concrete structures with corrosion.

Signs of corrosion of steel in concrete

Signs of corrosion of steel in concrete

Visual inspection and tapping of the structure: We must observe the signs of cracks and record the following signs throughout the structure

- Crack size: width, length

- Areas with a "thud" sound when tapping with a hammer

- Measure the diameter of the steel reinforcement after corrosion (if corrosion is detected)

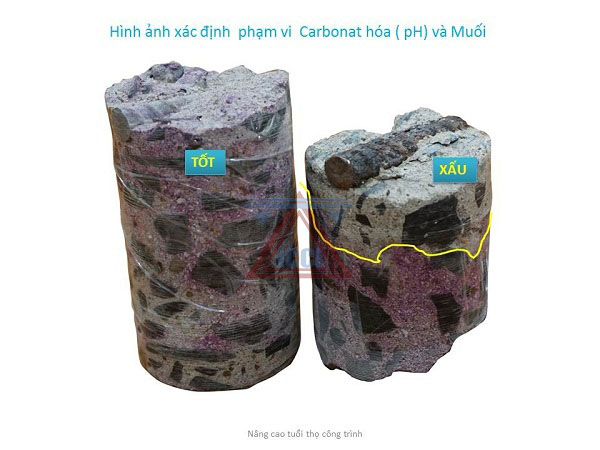

Measuring the thickness of the concrete layer using a non-destructive device Finding the depth of the carbonated concrete layer (Chemical experiment)

- Drilling samples

- Use a drill to take powder to accurately determine the pH in the laboratory, about 2 cm to take 1 sample

- Spray 1% Phenolphthalein reagent, distinguish and record the areas of concrete with white and red colors, the white area is the area of carbonated concrete

Carbonation of concrete test

Carbonation of concrete test

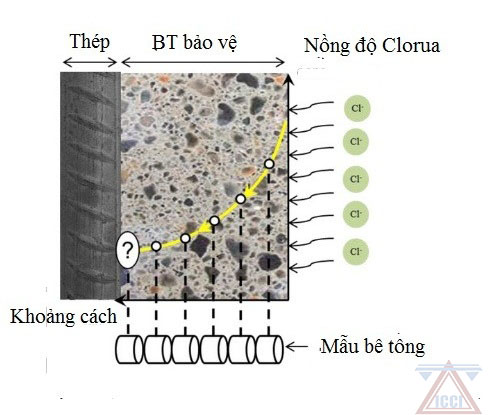

Find the amount of chloride (chemical experiment) distributed from the outside surface through the reinforcement position

- Drill powder in concrete, about 1-2 cm drill 1 sample, sample depth from concrete surface through steel bar position

- Determine the amount of chloride in concrete in the laboratory

- Draw a chloride distribution chart – figure 3

Chloride concentration distribution chart in concrete

Drill the sample to find the compressive strength

Measuring corrosion potential - figure 4

- Use a machine that has been tested for accuracy

- Cut open the steel rod and clean it to clamp the positive electrode

- Spray moisture on the concrete surface at the location to be measured

- Place the measuring electrode and read the number, pay attention to the stability of the reading

- Evaluate the measured corrosion potential with table number 3 to know the corrosion status of the reinforcement

Measure the corrosion potential of steel reinforcement in concrete

Measure the corrosion potential of steel reinforcement in concrete

Table for assessing the possibility of corrosion of steel reinforcement in concrete

(TCVN 9348 : 2012 - ASTM C 876-87)

Some basic items in the process of assessing whether or not steel in concrete is corroded. Based on these results, the structural engineer will propose a maintenance plan for the structure as well as anticipate the corrosion of steel in the future.

INTERNATIONAL CONSTRUCTION INSPECTION CONSULTANT JOINT STOCK COMPANY

Vietnames

Vietnames English

English